Measure the dimensional changes in cup, tray, pouch, can, lid and even jar during sterilization

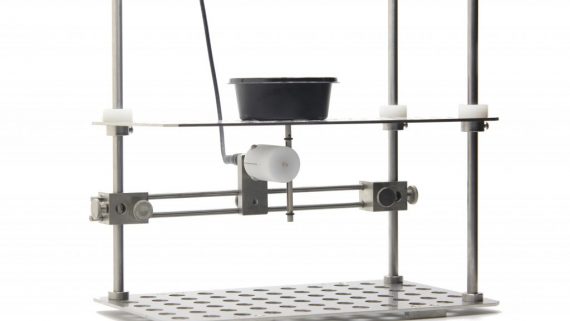

Description of the packaging deflection sensor

This sensor follows displacement and dimensional variations of all the surfaces of your packaging. Connected to the P&P Box or the Autonomous Display, it gives the deformation values and interpretations in real time. Ideal tool for the R&D department because it allows the adjustement of thermal process for optimizing quality product as well as productivity.

This sensor create no stress on packaging so measurements are very accurate. Thanks to its wide measuring range, it is suitable for all packaging formats.

Attributes of the packaging deflection sensor

Insertion in all retorts (optional rotary).

Stroke of the sensor: 44 mm .

Measuring sensitivity: 0.1 mm.

Measuring head adjustable on 360 °.

Watertightness: IP 68 under 5 bar.

Temperature resistance: from 0.5 °C to 130 °C (135 °C peak).

Specificities

Absence of return spring.

Possibility of attaching a custom touch point..

Connection to the central P&P Box Deformation or Expert to get real time data, analysis or even auto-calibration.

Fully maintenance free.

Requires our Universal mount to be properly installed.

Applications of the packaging deflection sensor

All packaging: tray, sealed or crimped plastic pot, pouch and even metal box like fish can or ready-meal can.

Quantifies pressure imbalance between the inside and outside of the packaging. Then, you get information to modify process pressure as wished.

Ring lift measurement and cap breathing identification.