Portfolio Category: Services_en

➜ Reduction of instantaneous steam requirements

➜ Limitation of compressed air injections

➜ Improvement of cooling efficiency

➜ correction of temperature and pressure profiles

➜ Respect of materials performance

➜ Taking into account the variability of production

➜ Manage the textures

➜ Improve the taste of your recipes

➜ Enhance final colour to meet your goal

➜ Improve heat treatment

➜ Increase in loading capacity

➜ Workshop performance optimization

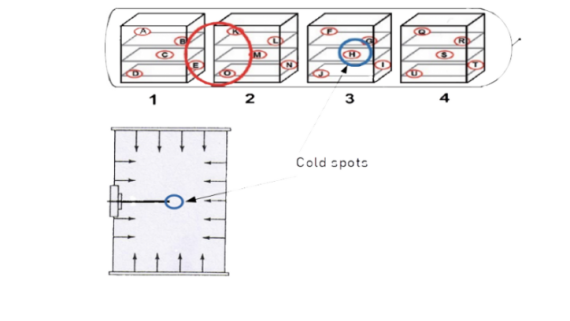

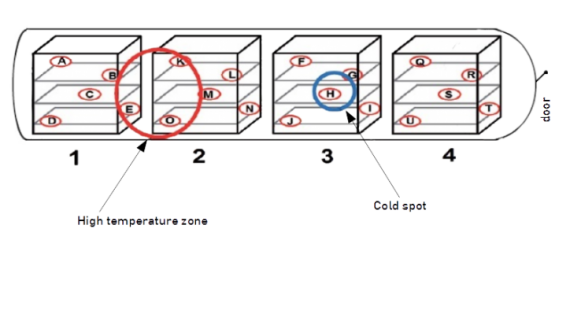

➜ Location of the cold spot in your product

➜ Location of the cold spot in the retort or continuous sterilizer

➜ Check that the thermal process provides the allowed PU or F0 even in the worst case scenario.

➜ Assurance of thermal homogeneity (retort exclusivity)

➜ Location of cold spot and hot spot

➜ Validation of maintenance work on your equipment

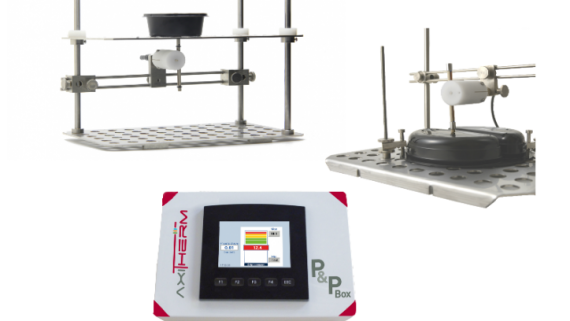

➜ Ensure temperature uniformity in the autoclave

➜ Validate heat penetration into products

➜ Ensure proper mechanical aspect on packaging

➜ Enhanced productivity and material yield

➜ Energy savings (steam, compressed air, water, electricity)

➜ Improved sensorial and nutritional properties