Measure the core temperature of the product in all types of processes: steam, water, cascade, mist and microwave.

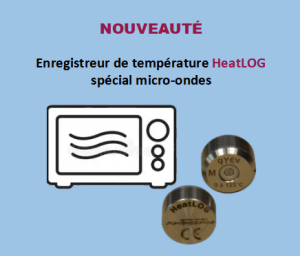

Description of microwave temperature logger

The HeatLOG temperature logger is designed to accept a variety of static or continuous heating processes. The environment can even be under vacuum or pressure (limited to 3 bar).

These performances make it suitable for use in all existing pasteurisation tunnels and retorts in the food industry : conventional and microwave heating process.

In addition, this microwave data logger is very compact and can be inserted into the narrow neck of a bottle.

HeatLOG accurately measures the temperature in the product or equipment and its software calculates the resulting F0 or PU.

Performances of microwave temperature logger

Environment temperature mesurement without disturbance

Weight of 6.1 g for a volume of 1.92 cm3

3 temperature ranges to meet all your requirements:

-40 to +85 °C / 0 to + 125 °C / +15 to +140 °C

High miniaturization: Ø 16.4 x 9.1 mm

Accuracy better than: ± 0.15 ° C

Watertightness: IP 68 from -1 to +3 bar

Memory capacity: 4096 data

3 recording modes: immediate – date / time – temperature thresholds

Insensitive to microwaves;

Direct food contact standards.

2 to 5 years lifetime upon the frequency of use.

Specificities of using in microwave oven / tunnel

Fastest acquisition speed = 1 measurement every 15 seconds.

Be sure that HeatLOG stays in contact with food product during process.

minimum gap to another metal part = 2 cm.

never cool HeatLOG with water, just room air (3 minutes away from heated product).

Applications for HeatLOG

This microwave temperature logger allows you to control pasteurization and sterilization of food products

Accurate F0 / PU in all packaging over 80g

Control of microwave tunnels for tempering or pasteurization

Temperature control in a narrow-necked bottle

Optimization of programme construction

Operation with AXITHERM communication interfaces and softwares