On your industrial site, our technical services strengthen your innovation, your level of quality, your production capacity and support you in reducing energy consumption.

Food retort expertise

Control and Quality Assurance = we identify the drifts and correct them if necessary

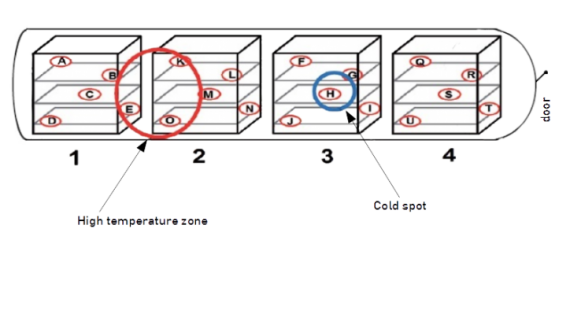

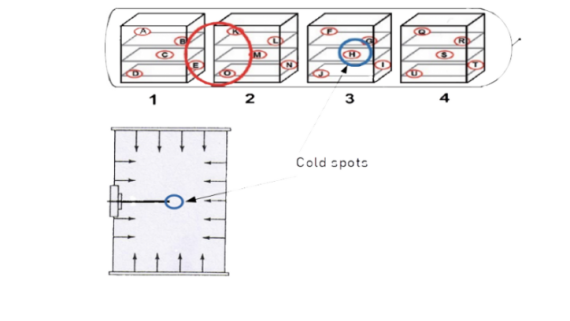

➜ Assurance of thermal homogeneity (retort exclusivity)

➜ Location of cold spot and hot spot

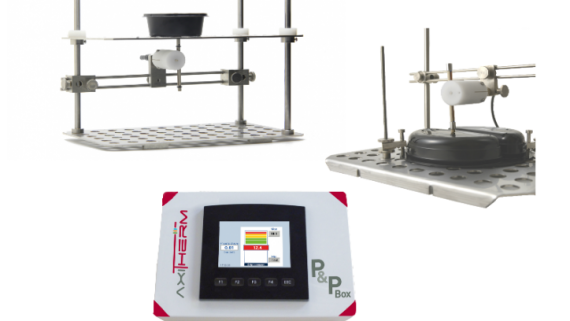

➜ Validation of maintenance work on your equipment

➜ Location of the cold spot in your product

➜ Location of the cold spot in the retort or continuous sterilizer

➜ Check that the thermal process provides the allowed PU or F0 even in the worst case scenario.

➜ correction of temperature and pressure profiles

➜ Respect of materials performance

➜ Taking into account the variability of production

Support for innovation = our food retort expertise secures and improves value creation.

➜ Improve heat treatment

➜ Increase in loading capacity

➜ Workshop performance optimization

➜ Reduction of instantaneous steam requirements

➜ Limitation of compressed air injections

➜ Improvement of cooling efficiency

➜ Manage the textures

➜ Improve the taste of your recipes

➜ Enhance final colour to meet your goal

We then call it O.T.T.A. for Optimisation of Thermal Treatment in Autoclave (retort).

Most of the time, the return on investment of this service is simply immediate.

In addition, our 30 years of food retort expertise guarantees that you will get the best energy efficiency from your equipment.