Glossary : food sterilization definition

In this section we are happy to share our knowledge of heat treatment in the food sterilization industry. As you will see, this vocabulary mainly concerns the pasteurisation and sterilization of pre-packed food products.

Here are some definitions of our main activity:

The retort cold spot designates the location of the load where the temperature is the lowest during heating period.

The packaging cold spot designates the place in the can where the Pasteurization Unit / Sterilization Value reached will be the lowest (sometimes located in the geometric center, but not always).

1st case: the F0 or PU taken into account only concerns the minutes accumulated during the heating period of the treatment. Then, the two concepts are consistent, hence a good correlation between the cold spot of the retort and the position of the packaging with the lowest F0 or PU. On the other hand, the choice not to consider cooling results in the ignorance of significant effects of overcooking, in particular on conductive produces.

2nd case: according to the method applied in France and in most European countries, the PU or F0 is calculated over the entire heat treatment: heating period + cooling period. Consequently, the concepts of retort cold spot and packaging cold spot are no longer equivalent! Thus, the location of the packaging with the lowest F0 can quite be opposite the retort cold spot. It all depends on the homogeneity of the cooling!

To avoid any error, it suffices to carry out a heat penetration study instead of an retort thermal mapping . The advantage of this method is to control the effects of overcooking during food sterilization with conductive produce. In fact, with pasty produce, it is frequent to accumulate more PU or F0 on cooling than in heating period.

Note: for very convective produce, retort thermal mapping may suffice since the PU or F0 acquired during cooling remains minimal.

In general, these "flexible packaging" are heat sealed (peelable seam, pouch, doy pack, tray, ...). Another use of the deformation measurement relates to the ring raising of the lids with easy opening, the bending of twist-off or the lid and bottom of the metal can. These more technical aspects will be dealt with separately.

The standard use of the deflection sensor aims to inform the operator about the fine balance between the pressure inside retort (Pext) and the pressure inside packaging (Pint) in food sterilization. One speaks about ∆D because it is the variation of Displacement of the wall compared to its initial position which interests us.

A bending (Positive deformation) indicates an excess of Pint, a hollow (Negative deformation) expresses an excess of Pext. This simplicity of interpretation allows retort control with appropriate automation.

However, some plastic packaging reacts locally in the opposite way due to geometric effect. Also it is advisable to remain vigilant with this type of automation.

To be fully operational, a Deflection sensor must be able to be installed on all sides of the packaging, without exerting mechanical stress (a spring system is to be avoided) and have a wide measuring range.

The Delta P calculation represents the pressure stress mechanically supported by the walls of a package during food sterilization or pasteurization, according to the formula:

Delta P = Pressure in the packaging – retort pressure

Delta P = Internal Pressure – External Pressure

The variation of delta P comes from several parameters:

• the variation of the external pressure (pressure profile)

• the variation of the temperature, which induces a variation of the internal pressure by expansion, vaporization (in the heating phase) or condensation / retraction (in the cooling phase).

Notes on Delta P behavior:

• For rigid packaging (jar or small diameter metal box), a decrease in the amount of gas initially enclosed in the packaging will increase the final value of the Delta P in case of heating.

• For semi-rigid or flexible packaging (large diameter metal box or plastic container), reducing the amount of gas initially enclosed in the packaging will decrease the final value of the Delta P in case of heating.

• Warning: for a flexible packaging (plastic container), the Delta P loses its relevance. In fact, it would take a very large deformation of the heated packaging to perceive a variation of pressure. In general, the packaging is denatured before displaying a significant variation of the Delta P. The exploitable indicator is then Delta D (packaging Deformation)

As with domestic microwave ovens, the presence of metal can generate destructive electric arc, especially for electronic equipment. Introducing an on-board sensor, containing metallic components, in order to take a temperature measurement therefore looks like a challenge.

Until recently, the only way to measure temperature was to use fiber optic probes. This device offers precise measurements but is difficult to accommodate continuous equipment and is always a delicate implementation. Its use is generally limited to development services, especially as its cost remains high.

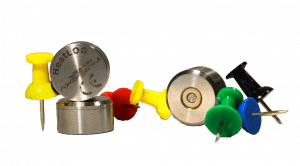

After a significant development on the extreme miniaturization of on-board electronics and the geometry of protective boxes, AXITHERM is proud to offer you recorders compatible with all microwave processes today. The range of HeatLOG loggers makes it possible to cover all the control and development needs for products treated by microwave, conventional heating or combined system.

On the other hand, in terms of vitamins and minerals, the degradation can be substantial. Indeed, excessive heating or an inappropriate plateau temperature can destroy your selection of high quality raw materials.

Thus, vitamins may have been damaged and minerals discharged into exudates which will be rejected by the consumer after opening the packaging.

Axitherm offers an original retort process approach, the so-called OTTA method, which best preserves the organoleptic and nutritional qualities of the recipe. It should also be noted that this approach maintains the entire production capacity of the retort.

To exploit the data transmission by radio in an retort, a cooking cell, or any other metallic and closed equipment, 2 methods are then possible: 1- Radio transmission inside the enclosure, then wired via the receiving antenna, the cable of which will pass through the metallic wall. The receiver is thus placed outside the equipment and can directly attack a display, a computer or a network. 2- Wired data transmission from inside to outside the enclosure, then a radio relay to the distant operating point (display, computer, network, ...).

The first method is attractive because it makes it possible to instrument retort with automatic loading, but has some limitations:

- high additional cost compared to wired sensors

- significant limitation of the number of sensors used simultaneously in the instrumented enclosure

- risk of communication breakdowns with rotary retort due to many metallic parts inside

The second method requires human intervention to connect the probe after charging but also has its advantages:

- no additional cost compared to fully wired probes

- up to 6 probes used simultaneously in the instrumented enclosure

- possibility of working in supervision on several enclosures

- no risk of communication breakdown.

AXITHERM offers you the 2 equipments to best meet your working methods.

Notes:

- for temperature measurement in a rotary retort, the accuracy observed with wired thermocouple probe using a rotary connector is extremely questionable (possible drift of several degrees), so we recommend wired PT100 probes or miniature temperature loggers or radio principles described above

- if real time is not essential, miniature temperature loggers are undoubtedly the most economical, precise, reliable and practical equipment to install simply because they do not need to get through to packaging unlike to the other 2 technologies.

In industrial reality, it must be recognized that this is only rarely the case; a process rarely lasts the same duration when the retort is full or just partially loaded.

The art of the programmer is to ensure that the process is always identical with the desired F0 / PU and the desired packaging aspect.

The programme which is nothing else a matrix of figures (time, temperature, pressure and sometimes speed of rotation, heating or pressure variation) translates the temperature and pressure profile expected from the retort. Profiles which will only be produced if they are in agreement with the equipment performances, energy networks and industrial filling dispersions (packaging and retort). Not so simple!

When validating a process, it is therefore essential to control the core product temperature in the most unfavourable conditions because the results will often be different from the standard case. We then see that the retort under partial load is commonly much more critical than under full load contrary to what is imagined.

Important note: Most modern retorts have several parameters to manage pressure and temperature controllers. These parameters are implemented by the installer and their function is to standardize the behaviour of the different retorts in presence (layout in relation to energy networks, load, design differences, etc.). Here, we understand that the quality of this setting is essential to ensure that the same programme will give the same result on all retorts.

Conversely, an obsolete or incorrectly calibrated setting will generate significant differences between retorts and therefore a dispersion of quality and F0/PU.

This correction consists in a new programme (i.e. a change in writing instructions) obtained by a rapid heat penetration study, coupled with pressure, deformation and flow measurements. Then we meet the acceptance criteria not reached by the standard process.

This method makes it possible to immediately find the operating approval of the retort without lengthening the cycle, neither modifying the Sterilization Value or the Minimum Pasteurizating Unit, nor investing in equipment.

For this, we proceed to the distribution of several temperature probe on a horizontal plane in the empty enclosure, without load. This method provides information concerning the automation (reactivity, measurement accuracy, etc.) but only allows the detection of big troubles.

Please note: even if the thermal reception map appears satisfactory, it does not predict anything about homogeneity of the heat treatment applied to the packaging, ie with a fully loaded enclosure.

This term is sometimes used to include the various studies and possible measures to control a heat treatment which are:

-The Thermal Mapping in open or closed enclosures (cell, tunnel, oven, sterilizer, retort …)

-The Heat Penetration in a packaged or unpackaged product

-The Process Validation to confirm the correct writing of the food sterilization programme.

It is therefore necessary to specify its nature. We use the above terminology to avoid confusion.

The goal of this Thermal Mapping is to locate the hot spot and cold spot of the equipment. To do this, we follow the temperatures in the enclosure at different hights. The distribution of the temperature loggers is established so as to study the entire volume of the treated load. It is recommended to have a minimum of 3 loggers per basket. It allows the automatism to be studied completely (Controller setting) as well as ensuring compatibility between the product loading plan and the performance of the retort.

Notes:

– depending on the design of the equipment, the study must be carried out with a partial load or following a load break (continuous sterilizer). These conditions can exacerbate the cold spot as well as the hot spot.

– although this mapping offers interesting results, it is recommended to validate them on several packaging sizes before being able to generalize. Indeed, the position of the retort cold spot can change with a modification of the loading plan, a new packaging geometry, a new programme or even an adjustment of the rotation speed

The final objective of a Thermal Mapping is to obtain a spatial representation of the temperature dispersion prevailing in the chamber to compare them with a previously defined acceptance grid. The first expected response from a Thermal Mapping is therefore approval to put the studied equipment into operation.

Our experience has shown us that a thermal mapping could result in a delicate observation: the acceptance criteria are not met!

“Thermal Mapping in Retort” is an exclusive developed by AXITHERM to avoid being blocked by this distressing finding.

- in a theoretical or regulatory framework (see FDA), the heat penetration will be carried out with a simulating product such as oil or bentonite, this to limit the measurement dispersions linked to recipes which would not be thermally homogeneous (frequent case). Water can also be used as a simulant in the packaging, but this can cause artificial shortages in the heating power of the retort.

- in the concrete context of the knowledge of PU or F0 acquired for a defined recipe so as to identify the minimum, maximum and average values. Please note: here, prior research and identification of the packaging cold spot is required. The information obtained makes it possible to describe not only the uniformity in temperature of the enclosure, but also in heat transfer; that is, the ability of the equipment to heat and cool the load evenly.

Explanation: air, steam, water or a mixture of these elements brought to a given temperature will not provide the same energy to the product. In the case of a mixture (air / steam or water / air / steam), the variation of the different proportions of the mixture induces significant fluctuations in the heat transfer potential. So, if the proportions of the mixture change with the position in the load (very frequent case), the heat transfer potential will also change.

These differences in heat transfer potential directly impact the dispersion of PU and F0. This is particularly true for small packages or products with convective heating. This dispersion is inherent in the packaging / processing equipment / programme combination.

The level of precision of the Heat Penetration makes it possible to qualify the reproducibility of the cycles and to define the operating limits of the devices with regard to the products treated.

When it is carried out on actual recipe, it also specifies the following information:

• the minimum F0 or PU and its location => essential for the bacteriological validation of the process .

• the maximum F0 or PU and its location => advantageous for validating the organoleptic acceptance of the product and making it possible to fix claims, in particular on the nutritional qualities of foods.

• the difference between minimum and maximum F0 or PU => assessment of the overall control of the process (filling, closing dispersions, integration of waiting time, construction of the programme, ...)

After identifying critical operating cases, the appliance cold spot and the packaging cold spot, the temperature measurements are made by combining all of these criticalities.

This study is cumbersome to set up but offers the advantage of calibrating bacteriological results with your method and measuring instruments. It is therefore essential information to calmly develop new recipes and the basis for optimizing your processes.

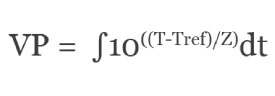

The values of Tref and Z then describe the behavioral law of a particular aspect of the produce, such as color, texture, speed of a vitamin destruction, etc.

There are therefore several possible Cooking Value for a homogeneous product and several tens of possible Cooking Value for a ready meal. This diversity makes it difficult to exploit, especially since the Tref and Z parameters are not always known to quantify the desired aspect.

Unlike PU or F0, the observation point will not necessarily be the "cold spot" but may be the "hot spot" to account for maximum degradation. This hot spot is on the periphery of the packaging and, more often than not, on the upper layer of the load treated.

Here, the values of Tref and Z are adapted to the microorganism that we particularly wish to study. There are thus a large number of possible PU calculations depending on the Tref and Z values used.

The couple Tref = 70 and Z = 10 ° C is very common; the target PU is generally 1000 minutes for a DLC of 42 days. It is important to specify the values of Tref and Z as soon as one makes comparisons under penalty of gross errors.

In practice, the Sterilization Value is the result of a calculation from the measurement of the cold spot temperature of a product. The term "F0 measure" used in the profession is therefore an abuse of language.

The values Tref = 121.1 ° C and Z = 10 ° C are imposed for the calculation of F0; they correspond to a reference germ: Clostridium Botulinum. By extension, we can say that: 1 minute spent at 121.1 ° C gives 1 point of F0.

Each product to be treated has a specific microbial load, varied in gender and number. It is therefore advisable to apply a suitable minimum F0 in order to guarantee industrial sterility (F0 = 3 is used as a minimum value by the FDA).

Conversely, the organoleptic qualities of a produce are often degraded by an excess of heat and therefore of F0. Mastering the quality of raw materials is therefore essential to guarantee the stability of products sensitive to cooking phenomena.

The accuracy of the F0 calculation is directly related to the accuracy of the temperature measurement, from which it is derived. The errors of temperature measurements have mainly 3 origins:

• positioning of the logger (error in tens of ° C = cold spot error)

• geometry / dimension of the probe (error in ° C = unsuitable control equipment)

• probe accuracy (error in tenths of ° C = expired calibration)

Note that the impact of the metrological quality of the probe is practically negligible compared to the impact of its dimensions or its positioning. The profession recommends using calibrated probes (at least once a year), with a maximum dispersion of ± 0.25 ° C for temperatures above 100 ° C. Instructs the user to check the location of the real cold spot (and not assumed) and the ability of its instrumentation to make a usable measurement (not so simple!)

Notion of minimum F0 and target F0:

The minimum F0 is the result of the F0 calculation obtained by combining the various factors unfavorable to the sterilization process, namely:

• conditions for filling the product in the packaging: temperature, weight, pressure, gas volume

• loading conditions: compacted layers, cold spot of the retort

• autoclaving conditions: critical load, critical maintenance of the retort and critical operation of the workshop capacity

The minimum F0 thus calculated must satisfy the level of destruction required, also called target F0. Thus, the stability of the product is guaranteed and responds to the term "canned food".

If the minimum F0 is lower than the target F0, an increase in treatment time or temperature is usually used to raise it. However, as we often practice at AXITHERM, it is possible to obtain the same result by reducing the dispersions of F0 (= increase value of minimum F0) by adapting the sterilization programme.

This method called OTTA makes it possible to avoid lengthening process time and overcooking.