Instrumentation pour la validation de la stérilisation et de la pasteurisation alimentaire

Experts en solutions de validation et pasteurisation alimentaire

AxiTherm vous accompagne dans la maîtrise de vos productions stérilisées ou pasteurisées avec une gamme d’équipements développés et sélectionnés pour répondre aux besoins de vos Services Qualité et R&D tant pour les mesures de température, de pression que de déformation d’emballage.

À titre d’exemple, HeatLOG est spécialement conçu pour la mesure de température lors de réchauffage micro-ondes (en batch ou en continu).

Applications et bénéfices

Logiciel ergonomique

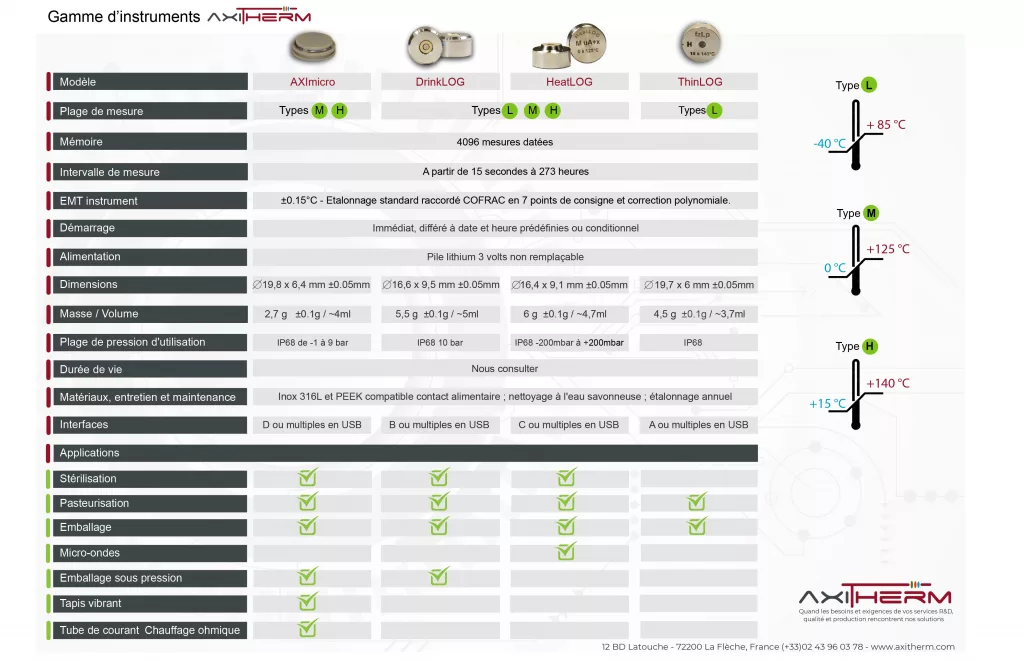

Instrumentation

Gains économiques

Gain de productivité des autoclaves,

amélioration rendement matière

ou économies d’énergie.

Maîtrise du produit emballé

L’intégrité des emballages est préservée.

Cartographie et validation

Nos solutions permettent la réalisation de cartographies thermique, mesures de pénétration de chaleur ou validation de barème.

Mesure de température

Notre technologie pour répondre aux exigences de vos produits,

emballages et procédés thermiques.

Mesure de déformation

Mesure de déformation des emballages pendant le traitement thermique.

Mesure de pression

Mesure de pression interne des

emballages pour garantir reproductibilité

et qualité produit.

Une équipe engagée à vos côtés

AxiTherm a pour vocation de développer des solutions adaptées aux enjeux de maîtrise de la production et de la qualité alimentaire.

Vos interlocuteurs privilégiés :

Vincent Quélin : Toutes questions techniques et demandes commerciales.

Frédéric : Production des matériels, service après-vente et métrologie.

Sabine : Responsable de l’administration des ventes.

Guillaume : Responsable du développement des logiciels et le SAV associé.

Solutions pour la maîtrise de la stérilisation et de la pasteurisation alimentaire

Solutions pour la maîtrise de la stérilisation et de la pasteurisation alimentaire

(+33) 02 43 96 03 78

12 boulevard Latouche

72200 La Flèche, France

Copyright Axitherm © - 2025