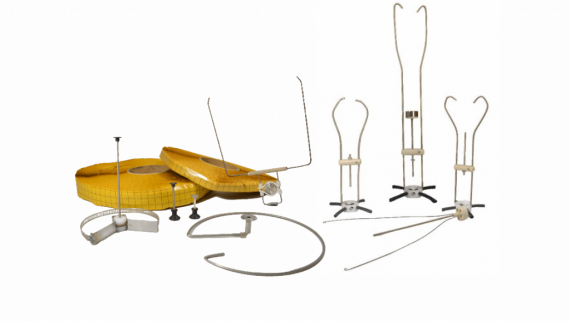

Temperature logger for bottles and cans containing still, fermented or carbonated drinks

Description of the pasteurisation temperature logger

The design of DrinkLOG has been studied to cover a wide range of applications, including bottles and cans. Its small diameter, high pressure resistance, fast response and suitability for all our mechanical supports (glued or screwed) make it very practical for the PU control of pasteurised beverages.

It is simply inserted directly into the product, no external mounting is required. The packaging is closed directly on the industrial line. This simplifies your controls and makes them perfectly representative of your process.

Performance

Miniature temperature recorder which does not disturb the environment:

weight of 5.6 g for a volume of 2.0 cm3

3 models to meet all your needs :

– 40 to + 85 °C / 0 to +125 °C / +15 to +140 °C

Dimensions : Ø 16.6 x 9.5 mm

Full scale accuracy better than: ± 0.15°C

Sealing : IP 68 from – 1 to +15 bar

Memory capacity : 4096 data

3 recording modes : immediate – date/time – temperature thresholds

Special features of the pasteurisation temperature logger

Direct contact compatible with foodstuffs

Adapted to all our mechanical supports

Can be used with all types of packaging

Total lack of maintenance

Lifetime = 3 to 5 years depending on frequency of use

Application of the pasteurisation temperature logger

DrinkLOG allows you to control the pasteurisation and sterilisation of food products whether they are solid or liquid, vacuum or pressure.

Accurate calculation of PU/Fo in all packages over 80g.

Optimisation of program construction.

Instrumentation of narrow-necked bottles and flasks.

Works with AXITHERM interfaces and software.