Nice data acquisition unit to record, identify, quantify and solve packaging trouble in retort process

Description of P&P Box Deformation

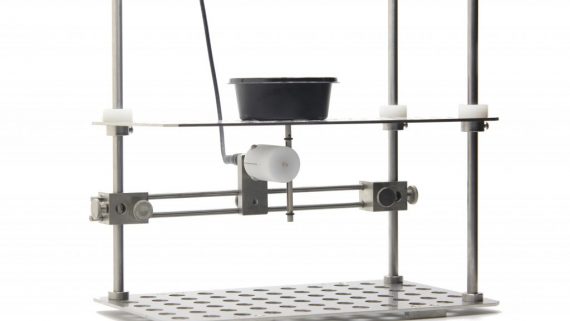

This P&P Box Deformation packaging acquisition center with integrated display allows the adjustment of your processes and programs in real time. It informs you about the modifications to be made in order to eliminate packaging deformations such as bending, delamination, leakage, hollow, …

So you can not only optimize the appearance of your packaging but also work on material thickness reductions.

Performances of the packaging deformation recorder

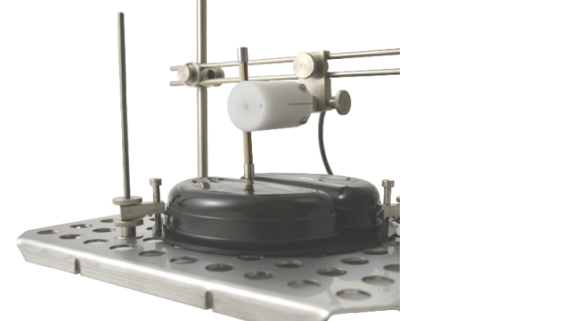

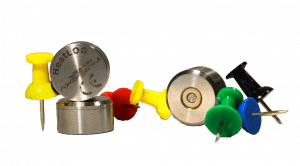

Housing with 1 to 2 Deflection probes +1 pressure sensor as standard.

Real time display and data acquisition.

Calculated values : pressures differential (3 input option).

3.7 inch color display, touch and waterproof (IP 66).

Memorization of 8 cursors with control of the correct writing of the program.

Export data in .csv.

Specificities of the packaging deformation recorder

All functions and displays accessible in real time.

Visualization of historical data and related information.

Calculation of pressure differential ( 3 input option) thanks to second deflection sensor = no need of pressure sensor inside.

Presentation of data in form: digital, graphic and statistics.

Assisted piloting: deflection, pressure differential (3 input option), program writing.

Main power supply.

Operation without a connected computer.

Application of the packaging deformation recorder

Elimination of packaging deformations: flexible or rigid plastics.

Production efficiency: metal cans (tab rising) and twist off leackage on jar.

Productivity gains: reduction in retort process time.

Packaging modification: material, thickness, geometry or performance (new supplier).