Retort process validation to identify minimum F0 / PU values in production

Aim of the thermal process validation

Provide a measurement report allowing the minimum Pasteurization or Sterilization Value applied to the recipe to be quantified and compared to the pre-defined target value.

The retort process study therefore has 2 complementary aspects:

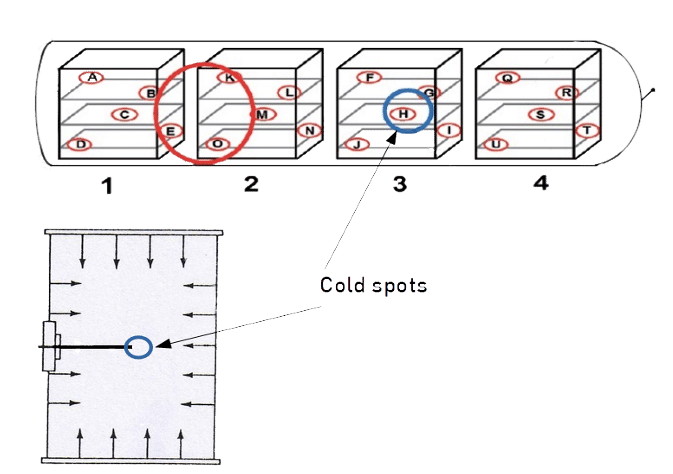

– first, the temperature heterogeneity of retort via (temperature distribution => thermal mapping. )

– second, the heat penetration homogeneity (heat distribution => heat penetration). At this step, all the production differences leading to a drop in temperature at the heart of the product must be cumulated. Then it becomes possible to identify the minimum PU or F0 that the thermal process can guarantee.

If the value obtained is lower than the target value, Axitherm will suggest different solutions for improvement.

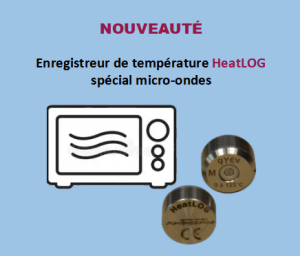

As the equipment used in the food industry is very varied, the instrumentation stage for themal process validation always requires a little reflection or even trial and error. Axitherm is constantly improving its fleet of loggers to allow you to obtain the best precision and values where information was sometimes lacking. Thus, we are now able to map ovens or microwave tunnels , nut pasteurizer and continuous fryers.

Thermal process validation methodology

Assessment on industrial site:

– search for the most suitable instrumentation for the configuration of the equipment (sensors installed internally, offset, with or without temperature rod, …).

– identification of the most penalizing load.

– location of the most pronounced cold spot of the retort.

– verification of the cold spot in the product.

Instrumented monitoring with the usual thermal process and accumulation of critical conditions (initial temperature, weight, cadence, headspace, …):

– temperature measurement and calculation of PU / F0.

Validation process:

– repeat the temperature measurement to check that the target PU or F0 is still reached.

Commitments for the thermal process validation study

Rapid development of special holders for temperature loggers if measurements need to be qualified.

Restitution within 30 days of the measurement report.

Possible recommendations on the management of the production line in order to guarantee a sufficient industrial safety margin.