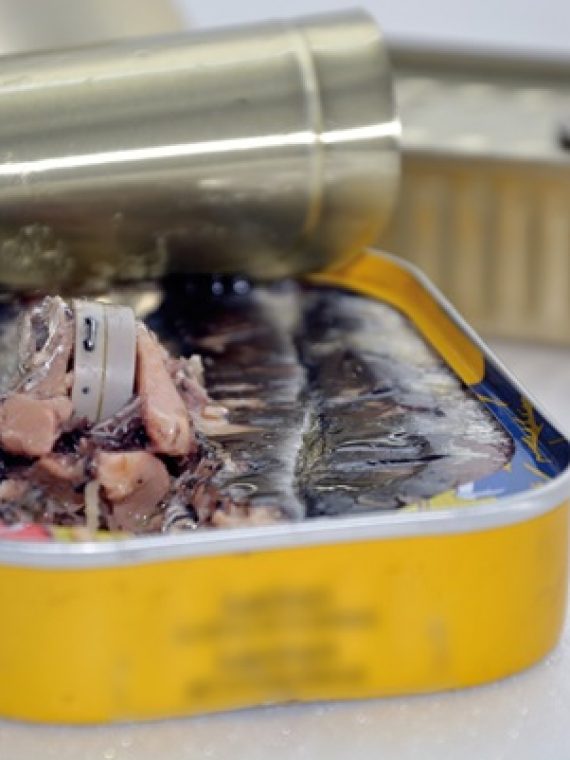

Measuring instruments and expertise adapted to fish and shellfish processing

Temperature measurement

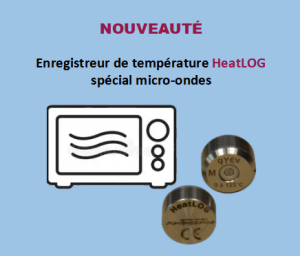

For Seafood sterilisation, the respect of heat process is a priority to preserve texture and material yield. Axitherm offers 3 models of data loggers suitable for temperature measurement. HeatLOG, ThinLOG or AXImicro loggers are designed for all your demanding applications:

• Extreme miniaturization for all the finest and smallest packaging.

• Supports vacuum and high pressure.

• Perfect for mapping with a high density load.

Control deformation during Seafood sterilisation

For consumers, the first indication of the quality of a product is the physical appearance of the packaging to the act of buying. Perfect geometry is therefore important for both safety and marketing.

• The probe for direct reading of deformation of pots and plates is common in baby food sterilisation.

• Can be placed on all sides to solve targeted defects.

• Adjustment of process to optimize thermal transfer or reduce packaging thickness.

Vacuum measurement in Seafood sterilisation

Another important thing to guarantee the appearance of the packaging is the respect of its internal vacuum:

• Digital display manometer.

• Qualifies capping and heat sealing injections (steam, gas).

• Measures the residual vacuum after treatment.

• Checks retort pressure.

Services and expertise for Seafood sterilisation

Product development and improvement:

• Optimization of cooking without changing the desired stability.

• Improvement of material yield.

Elimination of packaging deformations:

• Identification of the origin of the leaks, paneling and curved.

• Thermal process adjustment for new packaging and loading plans.

Energy saving on retort consumption:

• Reduction of steam injection and compressed air exhaust.

• Gain in cooling efficiency to reduce water consumption.

Productivity gains:

• Reducing process time without compromising quality (stability and organoleptic).

• Ensure process time repeatability.

Study of retorts, sterilizers and tunnels:

• Thermal mapping, location of cold spot and homogeneity control.

• Heat penetration study.

• Process validation in worse case scenario.